A high performance drier and ink conditioner, containing a revolutionary drying formula which greatly accelerates the drying rate.

Benefits:

- provides both surface and through drying

- Works on any substrate

- Smooths out solids

- Reduces salting and stripping

Usage :

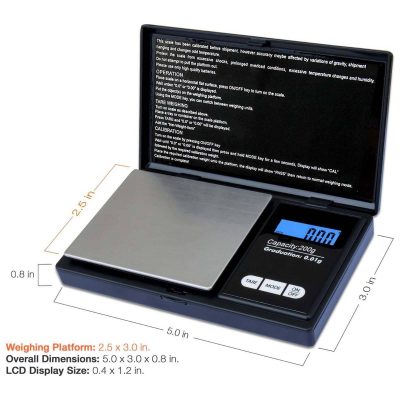

Adding directly 2%-or up to 5%(by weight ) Quick DrierPlus to ink , mix well.

Non toxic: it does not contain toxic or excessive chemicals and meets the environmental quality requirements of OSHA and ECC

Why use Driers?

Driers, also known as drying agents or accelerators, are often used in letterpress printing inks to help expedite the drying process and improve the overall quality of the printed material. Letterpress is a printing method that involves transferring ink from a raised surface (usually a metal or polymer plate) to paper or another substrate. Here are some reasons for using driers with letterpress inks:

- Faster Drying: Letterpress inks typically contain oils and solvents, which can take a long time to dry naturally. Driers contain chemical compounds that help catalyze the oxidation of these oils and solvents, accelerating the drying process. This is especially important in commercial printing settings where fast production is crucial.

- Improved Print Quality: Using driers can enhance the sharpness of the printed image by reducing ink spread and dot gain. This results in crisper lines and more vibrant colors.

- Reduced Ink Smudging: By speeding up the drying process, driers can minimize the chances of ink smudging during handling, stacking, or packing the printed materials.

- Reduced Set-off: Set-off occurs when freshly printed sheets stick together, causing ink to transfer from one sheet to another. Driers can help prevent this issue by promoting faster ink drying.

- Enhanced Ink Stability: Driers can help maintain the stability and consistency of the ink on press, reducing the need for constant adjustments and ink replenishment during the printing run.

- Increased Productivity: Faster drying times mean quicker turnaround for print jobs, which can lead to increased production efficiency and reduced lead times for clients.

- Compatibility with Different Substrates: Driers can be adjusted to accommodate various types of substrates, including different paper stocks and coatings, to ensure the ink dries properly on each material.

It’s essential to use driers with caution and follow manufacturer recommendations and safety guidelines because excessive or improper use of driers can lead to issues such as ink skinning, cracking, or poor adhesion. The choice of drier and its concentration should be tailored to the specific ink formulation, substrate, and printing conditions to achieve the best results.

In summary, driers are valuable additives in letterpress inks to speed up drying, improve print quality, and enhance overall efficiency in the printing process.