PawClaws Gauge Pins

£25.00 plus VAT

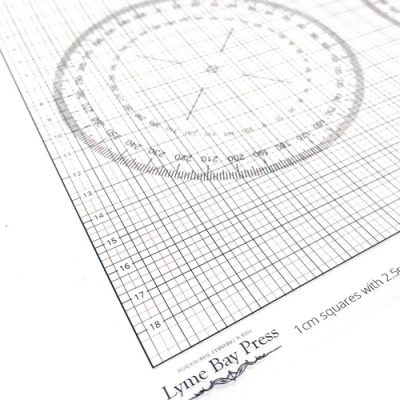

Lyme Bay Press - Flexible Tympan - A3

£9.50 plus VAT

No.1 Printers Hard Dry Sealing Varnish

£11.50 plus VAT

No.1 Printers Hard dry Sealing Varnish for uncoated boards

12 in stock

SKU:

LBP_Varn

Categories: Ink & Things, Pressroom Supplies, Roller Cleaner, Varnish, Varnish

Description

New to us and very well tested a hard dry sealing varnish for use when you want to print lighter colours, fluro or metallics on to uncoated boards. By sealing the paper you have a better chance of maintaining the vibrancy of lighter inks.

Rule 1: Your registration needs to be sound, you will leave your forme/plate in place whilst the varnish dies and seals your board.

Rule 2: Ink the varnish up as you woud any other ink.

Rule 3. To make things really pop you may want to over print the varnish with an opaque white ink.

Rule 4. This can be a time consuming process and you will need patience, like most things Letterpress, you can pop your initial prints somewhere warm and drying to speed up the process if you can’t wait.

Rule 5. When you’re finished just clean your press using our water miscible press wash and then add your next ink when everything is dry.

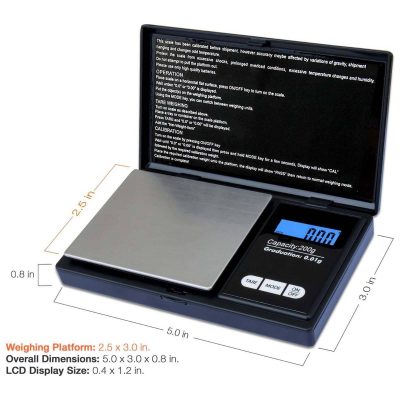

200g net

MSDS Information. Hard Dry Sealer MSDS 2016

Additional information

| Weight | 0.25 kg |

|---|---|

| Weight |

200g net in tin |

Shipping & Delivery

You may also like…

2″ Ink Knives

£17.78 plus VAT

3″ Ink Knives

£21.00 plus VAT